Blogs

The Future of Printing Technology: Why Businesses Are Turning to UV Printing

Table of Contents

The global economic landscape, driven by relentless technological advancement, is forcing the printing sector into a necessary metamorphosis. Obsolete production methodologies, once the standard operating procedure for enterprises across Pakistan, are being superseded by sophisticated digital systems that guarantee enhanced performance, ecological responsibility, and unmatched visual fidelity.

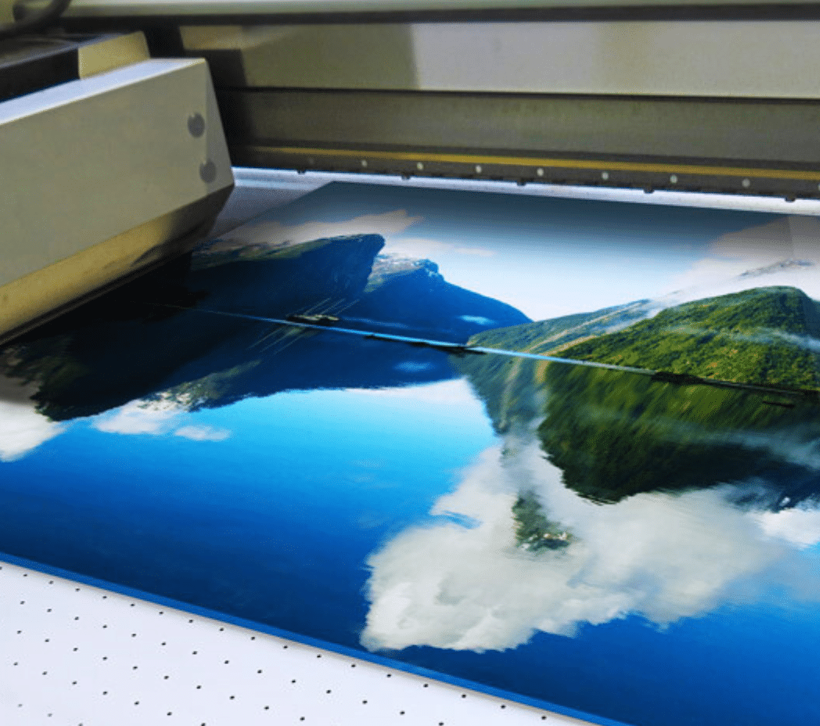

Pioneering this industrial pivot is Ultraviolet (UV) Solidification Technology. This advanced digital technique utilizes focused UV light sources to instantaneously cure specialized polymer inks, creating resilient, incredibly vibrant images across a vast range of media.

Nowhere is the absorption of this technology more critical than in Punjab. As Pakistan’s chief commercial engine, home to bustling hubs like Lahore, Multan, and Faisalabad, the province’s businesses are aggressively seeking technological advantages in a fiercely contested marketplace. UV printing offers precisely the kind of future-proof solution they require.

Punjab’s diverse industrial ecosystem—spanning textiles, large-scale manufacturing, agribusiness, and retail distribution—demands bespoke, premium-grade graphic solutions for corporate identity, product packaging, and promotional collateral. UV curing delivers a functional versatility that legacy processes, such as lithographic or silkscreen printing, simply cannot afford. Key industry leaders, like Vibrant Colour, a foremost provider of UV printing services in the region, are actively spearheading this transition, partnering with local firms to dramatically elevate their offerings through state-of-the-art imaging capabilities.

This discussion aims to demystify the science of UV curing, detailing its core benefits, the compelling factors driving its growing preference among Punjab-based enterprises (supported by relevant market data), and a glimpse into emerging trends. Whether managing a niche design studio in Lahore or commanding a large factory floor in Sialkot, comprehending the power of UV technology is indispensable for unlocking new competitive opportunities.

The Science of Instant Adhesion: Unpacking UV Curing

UV printing employs specialized, liquid polymer inks activated by intense ultraviolet energy. This differentiates it fundamentally from conventional inks, which require time for solvents to evaporate or absorb fully into the substrate.

The critical phase in UV curing occurs the moment the pigmented liquid is deposited onto the material. Precisely engineered UV radiation is applied instantly, which triggers a rapid photochemical process. This reaction solidifies the ink immediately, locking the pigments in place and preventing any spread, bleed, or saturation into the substrate. The result is a pinpoint-sharp, durable image bonded firmly to challenging surfaces that traditional inks struggle with, including acrylic, glass, dense ceramics, metal sheets, and wood veneers.

Modern UV apparatus frequently incorporates highly efficient, LED-based UV lamp arrays, significantly lowering power consumption. These units can process a wide variety of substrates often without requiring extensive pre-treatment stages, accelerating the overall production cycle and enhancing cost-effectiveness. In Pakistan, where minimizing environmental impact and maximizing resource utility are increasingly prioritized, UV technology excels, producing negligible material waste and relying on cleaner inks with drastically reduced levels of Volatile Organic Compounds (VOCs).

For manufacturers and service providers operating in Punjab, this translates into the capacity to rapidly produce everything from durable, high-impact exterior displays to meticulously personalized product containers—all without the lengthy delay associated with drying times or complex multi-stage production processes. Specialists like Vibrant Colour have perfected the deployment of this technology, ensuring the transformation of basic materials into sophisticated, enduring products with exceptional precision.

The Ascendant Advantages of UV Printing for Enterprises

Ultra-violet (UV) printing technology is rapidly gaining traction across various industries, offering a compelling suite of advantages that directly tackle contemporary business challenges. Its growing adoption underscores its fundamental importance, as explored in detail below:

Core Advantages Driving Business Success with UV Printing

- Unrivalled Quality and Vividness: At the forefront of UV printing’s allure is its unparalleled output quality. The immediate solidification of inks under UV light eradicates concerns like color bleed, yielding breathtakingly sharp and vividly saturated images. This translates into eye-catching, high-definition visuals that truly stand out. For sectors like Punjab’s dynamic textile and fashion landscape, this capability ensures that decorative elements on leather goods, for instance, maintain their brilliant hue and crisp detail through extensive wear and tear.

- Exceptional Durability and Resilience: Beyond aesthetics, UV printing excels in resilience. The inks, once cured, form an incredibly robust layer that resists scratches, repels water, and defies fading. This inherent toughness makes them perfectly suited for demanding environments – imagine vibrant billboards enduring Lahore’s characteristic humidity, or decorative ceramic tiles gracing homes for years without degradation. Such enduring quality directly translates to significant savings by minimizing the need for frequent replacements.

- Expansive Material Adaptability: A defining characteristic of UV technology is its remarkable material versatility. It effortlessly applies vivid designs onto an expansive range of substrates, from elegant glass for architectural elements to robust wood for bespoke furnishings. This expansive compatibility unlocks novel possibilities for design and production. Within Punjab’s industrial heartlands, this translates into unprecedented opportunities for product individualization, exemplified by custom-printed acrylic fixtures for retail merchandising.

- Heightened Speed and Operational Efficiency: The absence of traditional drying periods is a cornerstone of UV printing’s efficiency. This ‘instant-dry’ capability drastically accelerates production cycles, compressing tasks that previously consumed days into mere hours, thereby supercharging overall productivity. For high-velocity industries, such as Faisalabad’s competitive advertising sector, this agility is crucial for punctually delivering campaigns of uncompromised excellence.

- Commitment to Environmental Stewardship: UV printing also aligns strongly with environmental responsibility. The inks utilize significantly fewer volatile organic compounds (VOCs) and the process generates less material waste, resonating with burgeoning global sustainability mandates. As environmental compliance becomes increasingly stringent in Pakistan, companies embracing UV solutions can actively diminish their ecological footprint, simultaneously attracting a growing demographic of environmentally aware customers.

- Long-Term Fiscal Prudence: While the upfront investment for UV printing equipment might seem more substantial, the operational economics tell a different story. Reduced ink consumption, minimized material wastage, and accelerated project completion collectively translate into significantly lower long-term operational costs. This makes premium-quality printing approachable for even smaller enterprises in Punjab, with firms like Vibrant Colour offering competitive solutions tailored to regional needs.

Collectively, these advantages powerfully elevate brand perception, streamline operational expenditures, and cultivate fresh revenue streams, positioning UV printing as a pivotal strategic investment for forward-thinking organizations.

UV Printing’s Growing Footprint in Punjab, Pakistan

In Punjab, Pakistan’s most densely populated and industrially robust province, the embrace of UV printing is particularly pronounced. The local economy, a powerhouse spanning agriculture, textiles, and a vibrant SME sector, constantly seeks innovative methods to maintain its competitive edge on the international stage. Conventional printing techniques, despite their steadfastness, are increasingly proving inadequate in terms of production pace and material adaptability, accelerating the shift towards advanced UV solutions.

Across the province, cities are leveraging this technology distinctively. Lahore, the bustling cultural and commercial hub, is seeing a transformation in signage and promotional displays, with UV-printed glass and acrylic injecting a modern aesthetic into iconic locales like Anarkali Bazaar. Faisalabad’s renowned textile industry is harnessing UV capabilities for customizing leather and canvas products, crucial for both local and export fashion markets. Even in agricultural centers such as Multan, UV-printed ceramic tiles are merging traditional artistry with contemporary home and office interiors.

Pakistan’s printing and packaging sector, valued at approximately $5.5 billion, sees a substantial portion of its activity concentrated in Punjab’s extensive manufacturing base. This growth is propelled by escalating urbanization and a burgeoning middle class, driving an unprecedented demand for personalized and high-quality printed goods. Strategic initiatives, including productivity improvement schemes within the printing and packaging domain, are further stimulating this technological transition.

Local entities like Vibrant Colour, headquartered in Pakistan, embody this forward momentum. By providing bespoke UV printing services designed for regional requirements, they enable businesses throughout Punjab to access cutting-edge global technology without the complexities of foreign equipment import, thereby reinforcing the “Made in Pakistan” economic philosophy.

Evidencing Growth: Statistical Insights into UV Printing’s Rise

The trajectory of UV printing’s ascent is unequivocally highlighted by market data, both globally and within Pakistan. Projections indicate that the worldwide UV printers market is set to expand robustly, escalating from USD 1.02 billion in 2025 to USD 1.54 billion by 2030, marking a Compound Annual Growth Rate (CAGR) of 8.59%. This expansion is part of a larger trend within the digital printing market, which is anticipated to reach a valuation of USD 49.3 billion by 2033, growing at a CAGR of 5.5%.

Domestically, Pakistan’s printing industry commands an annual turnover of Rs 425 billion, with expert analysis suggesting a potential to generate between $8 billion and $16 billion annually if its capabilities are fully optimized. The market for UV curable inks specifically anticipates sustained growth leading up to 2031, fueled by increasing adoption in both offset and LED curing processes. In Punjab, this industrial advancement is further bolstered by the strategic integration of advanced German printing technologies and a persistent focus on maximizing resource efficiency. These figures collectively paint a clear picture of a paradigm shift towards intelligent, sustainable, and technologically advanced printing practices, with UV printing at the vanguard.

Market Segment | Current Value (USD) | Projected Value (USD) | CAGR |

Global UV Printers | 1.02B (2025) | 1.54B (2030) | 8.59% |

Global Digital Printing | 30.5B (2024) | 49.3B (2033) | 5.5% |

Pakistan Printing & Packaging | 5.5B | N/A | Growing steadily |

Pakistan UV Curable Inks | N/A | Forecast to 2031 | Positive growth |

Harnessing the Potential of UV Curing Technology: Bespoke Fabrication and Creative Materialization

Vibrant Colour elevates concepts into tangible reality through the exceptional adaptability of specialized direct-to-substrate UV printing applications, providing unparalleled material enhancement across diverse media:

- Plexiglass (Acrylic) Fabrication: Perfect for backlit installations and dimensional displays, producing a stunning interplay of light, color saturation, and perceived depth, ideal for luminous corporate signage.

- Architectural Glass Treatments: Imprinting transparent, resilient designs onto windows and decorative partition panels, ensuring enduring clarity and permanent adhesion for long-term architectural integrity.

- Earthenware Surface Customization: Transforming standard ceramic tiles into bespoke artistic elements, creating unique visual narratives suitable for high-impact kitchen backsplashes and sophisticated home decor features.

- Tannery Goods Embellishment: Imparting elevated aesthetics and distinctive surface patterns onto leather accessories, high-fashion goods, and luxury fittings, instantly increasing product sophistication.

- Lumber Substrate Enhancement: Applying rich graphics that complement and accentuate the inherent grain and texture of wooden materials, suitable for unique dimensional signage and commissioned artworks.

- Textile Art Reproduction: Generating high-fidelity, color-accurate archival prints on canvas media, ensuring striking visual intensity and longevity for fine art reproductions.

- Idiosyncratic Project Handling: Providing expert manufacturing solutions for unprecedented challenge requests, utilizing the unparalleled direct-to-substrate capability across virtually any composition or material imaginable.

These highly accurate, innovative manufacturing processes are essential for driving creative sectors across the Punjab region—from avant-garde haute couture houses in Lahore to leading architectural and interior design practices found in Rawalpindi.

The Evolving Horizon of UV Printing Technology

The trajectory of UV printing points towards a period of remarkable innovation. Artificial intelligence is set to revolutionize curing processes, delivering unparalleled gains in both operational efficiency and product quality. A broader spectrum of colors and enhanced compatibility with diverse substrates will unlock previously unimagined creative applications. Furthermore, a strong commitment to environmental stewardship will drive the widespread adoption of low-migration ink formulations and advanced LED curing solutions, significantly curtailing ecological impact.

Specifically within Punjab, the convergence of sophisticated digital workflows and advanced automation will be instrumental in boosting productivity. These local developments align perfectly with global movements, including breakthroughs in inkjet technology and a universal push towards more eco-conscious manufacturing practices. Forward-thinking suppliers, such as Vibrant Colour, are already positioned as frontrunners, eager to implement these transformative industry shifts.

Conclusion: Embrace the Future with UV Printing

The dynamics of the print industry are rapidly shifting, positioning UV curing technology as a crucial competitive differentiator for companies operating within Punjab, Pakistan. This cutting-edge method provides a direct route to enhanced modernization, operational streamlining, and greater environmental responsibility.

Given its documented advantages, compelling market expansion rates, and demonstrable forward momentum, the adoption of specialized UV printing solutions is becoming an imperative, not merely an option, for forward-thinking organizations.

Vibrant Colour stands ready as your dedicated partner, eager to translate your ambitious production goals into tangible results through our proven expertise in UV application. Initiate a dialogue with us immediately by visiting https://vibrantcolour.pk/ to explore the profound impact UV technology can have on redefining your commercial output.